Rising Sewer installation, Dorset, Southern England

Contributing to critical infrastructure

Read More

A selection of recently completed projects that we hope you find interesting

Contributing to critical infrastructure

Read More

Drilling ducts for tiebars

Read More

Night working on the M1 installing cross carriageway ducts

Read More

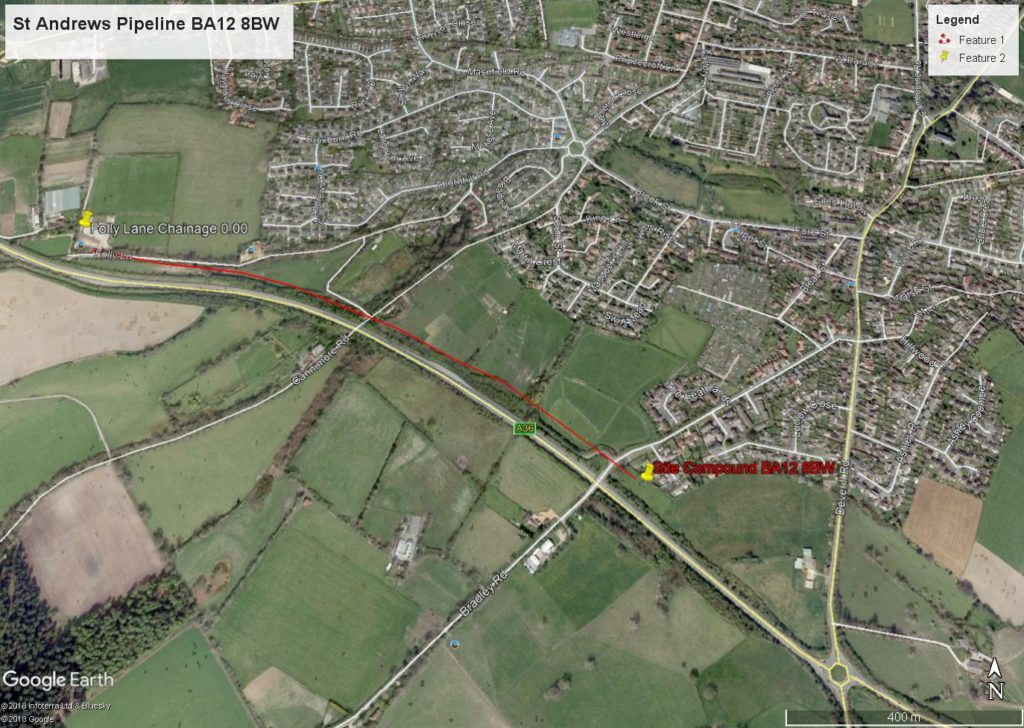

Directional drilling of water main to avoid critical infrastructure

Read More

Installation of 3 HPPE Plastic 180mm diameter ducts

Read More

Horizontal Directional Drilling

Read More

Hotel Network Connection

Read More

Directional Drilling / Connection / Pressure Testing

Read More

Horizontal Directional Drilling

Read More